Limit switches are the ubiquitous "sentinels" of automation control systems. They silently send critical signals at decisive moments, ensuring the safe and precise operation of mechanical systems. Understanding what triggers them is key to grasping modern industrial automation.

What Are Limit Switches?

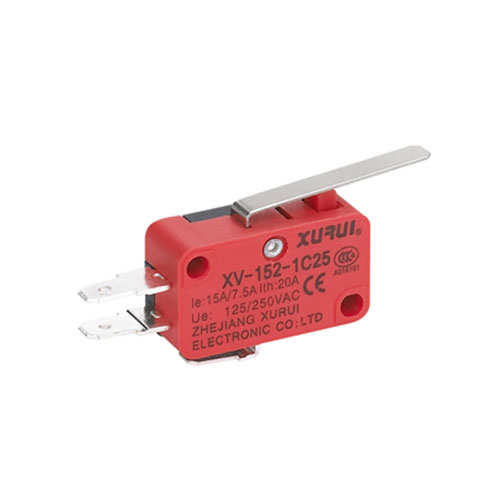

A limit switch is a electromechanical position sensor. Its core function is to detect the presence, position, or travel limit of an object. It typically consists of a rugged housing, a physically actuated actuator (like a lever, roller, or plunger), and an internal precision snap-action switch mechanism. When an external object contacts and moves the actuator to a preset position, the switch's internal contacts change state instantly (from "open" to "closed" or "closed" to "open"). This sends a clear electrical signal to a control system: "Target reached" or "Action must stop."

What Triggers a Limit Switch?

A limit switch is triggered by physical motion or a change in position of an object, usually by a mechanical force. Here are the main triggers:

1. Mechanical Actuation: The most common trigger for a limit switch is physical contact with the actuator. As a moving part (such as a conveyor belt or robotic arm) contacts the actuator, the mechanical force shifts the switch from one state (normally open or normally closed) to another, thereby triggering the electrical circuit.

2. Rotational Movement: In some applications, limit switches are activated when a rotating part reaches a predetermined angle. This can be seen in rotary limit switches, where the actuator is designed to respond to the rotation of a shaft or wheel.

3. Push Buttons or Levers: Some limit switches have push buttons or lever arms that require manual interaction. These buttons or levers are triggered when a part of the machine or the environment makes contact.

4. Proximity Detection: Some advanced limit switches use proximity sensors to detect objects nearby without requiring physical contact. These can be magnetic, optical, or inductive in nature, and they provide a non-contact means of triggering the switch.

5. Adjustable Set Points: Many limit switches allow users to adjust the position at which they are triggered. This makes them versatile for a variety of applications where the triggering point may need to be fine-tuned.

Limit Switches Applications

Limit switches have a broad range of applications, particularly in industries where machinery automation and safety are crucial. Common uses include:

1. Machine Safety: In many industrial environments, limit switches are used to ensure that machines operate within a safe range of motion. For example, they can stop motors if the machine reaches the end of its movement range, preventing damage to the equipment.

2. Position Sensing: Limit switches are used to detect the exact position of moving parts. For example, they can determine if a lift or elevator has reached its maximum height, or if a robotic arm has completed its task.

3. Conveyor Systems: In conveyors, limit switches can be used to detect the presence of objects or ensure the system has completed a task before starting another. They can also be used to stop the conveyor if an item is stuck or misaligned.

4. Automated Doors: In automated doors, limit switches are used to detect when a door has opened or closed fully. When triggered, they activate the corresponding motor to stop or reverse the door’s movement.

5. Industrial Equipment: Limit switches are used in cranes, presses, and other heavy-duty machinery to prevent over-travel and ensure proper functioning.

How to Install a Limit Switch?

Installing a limit switch requires careful consideration of the application and the environment where it will be used. Below are the general steps to install a limit switch:

1. Determine Mounting Location: Choose a location where the switch will be triggered appropriately by the moving part. This could be a position along a conveyor, a robotic arm’s path, or at the end of a lift’s travel.

2. Secure the Switch: Limit switches must be securely mounted to prevent misalignment. This can be done with bolts, clamps, or other mounting hardware, depending on the switch design and application requirements.

3. Connect Electrical Wiring: Once the limit switch is mounted, connect the electrical wires from the switch to the control system or motor. Ensure that the correct voltage and wiring configuration are followed as per the manufacturer’s instructions.

4. Adjust the Actuator: If the limit switch has an adjustable actuator, calibrate it to the desired position. This might involve setting the travel distance or adjusting the sensitivity of the switch to specific forces.

5. Test the System: After installation, it is crucial to test the system to ensure that the limit switch triggers at the correct position. Check that the machinery responds appropriately and safely.

Conclusion

The limit switch is a simple yet indispensable component in industrial control. Its core function is translating precise physical position into a definitive electrical signal. From heavy machinery safety limits to everyday appliance control, it remains vital in the digital age due to its high reliability, strong noise immunity, and intuitive operation. A solid understanding of its triggering mechanism, applications, and installation is essential for anyone in equipment maintenance, automation, or engineering.

FAQ

Q1. What is the difference between a limit switch and a proximity switch?

A: A limit switch typically requires physical contact to activate, whereas a proximity switch uses non-contact sensing (e.g., magnetic or inductive) to detect the presence of an object.

Q2. Can a limit switch be used in outdoor environments?

A: Yes, limit switches can be used outdoors, but you should ensure they are rated for environmental conditions such as moisture, dust, or extreme temperatures.

Q3. How do I know if my limit switch is faulty?

A: If the machine does not stop or continue as expected, or if you notice erratic behavior in your system, the limit switch might be faulty. You can check its operation by manually activating the switch or using a multimeter to check the electrical continuity.

Q4. Can limit switches be used in high-speed applications?

A: Yes, but it is important to choose the right type of limit switch that can handle the speed and force of the application without wear or failure.

Q5. Are limit switches adjustable?

A: Many limit switches feature adjustable actuators that allow users to set the trigger point for the switch based on the application’s needs.