Micro switches are widely used electromechanical components known for their high precision, fast response, and reliability. They play a critical role in sensing position, motion, or the presence of an object in many industrial and consumer applications. This article explains what a micro switch is, how it works, how it is constructed, its main uses and precautions, and how to maintain it properly.

What Is a Micro Switch?

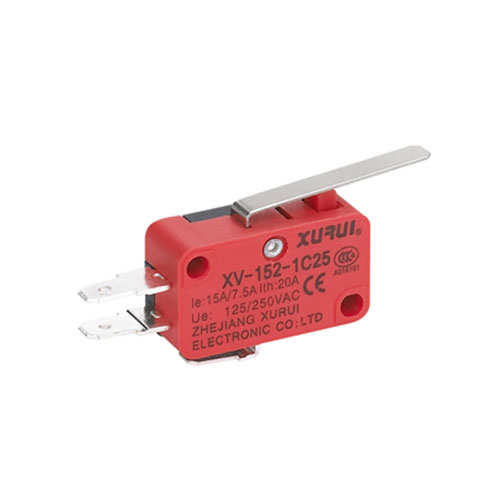

A micro switch, also known as a snap-action switch, is a type of switch that is activated by a very small physical force. Once the actuator is pressed to a certain point, the internal contacts change state instantly, providing a quick and reliable electrical signal. Because of this snap-action mechanism, micro switches offer high accuracy and repeatability, even after millions of operations.

The Use of Micro Switch and Precautions

Common Uses of Micro Switches

Micro switches are used across many industries, including:

-

Industrial automation: Position detection, limit control, and safety interlocks in machines

-

Home appliances: Door detection in microwave ovens, washing machines, and refrigerators

-

Automotive systems: Brake lights, door locks, seat position sensing

-

Medical equipment: Precise position and safety detection

-

Consumer electronics: Buttons, levers, and mechanical control feedback

Precautions When Using Micro Switches

To ensure safe and reliable operation, the following precautions should be observed:

-

Do not exceed electrical ratings (voltage and current), as this can cause contact welding or failure

-

Avoid excessive mechanical force, which may damage the actuator or internal spring

-

Ensure proper mounting alignment to prevent uneven stress on the switch

-

Protect against dust, moisture, and corrosive environments unless a sealed micro switch is used

-

Avoid frequent overtravel, which can shorten the switch’s lifespan

How Does a Micro Switch Work?

The working principle of a micro switch is based on the elastic deformation and snap-action of the reed spring. The specific process can be divided into the following steps:

-

Initial State: In the natural state, the reed spring is in a stable equilibrium position, which determines the initial state of the contacts. For a normally open micro switch, the contacts are separated; for a normally closed one, the contacts are closed.

-

Force Application: When an external force acts on the actuator, the force is transmitted to the reed spring. As the force increases, the reed spring begins to deform elastically, but it still maintains its original equilibrium position within a certain range.

-

Snap-Action Trigger: When the applied force reaches the "operating force" (a preset threshold) of the micro switch, the reed spring will quickly snap from the original equilibrium position to the other equilibrium position due to the sudden change of elastic force. This process is extremely fast, usually completing within a few milliseconds.

-

Contact Switching: The snap movement of the reed spring drives the contacts to switch state—normally open contacts close to connect the circuit, and normally closed contacts open to disconnect the circuit.

-

Reset State: When the external force is removed, the reed spring returns to its original equilibrium position under the action of its own elasticity, and the contacts also reset to their initial state, completing a switching cycle.

This snap-action mechanism ensures that the micro switch has a fast switching speed and clear contact separation, which can effectively reduce arcing and prolong the service life of the contacts.

How Is a Micro Switch Constructed?

A typical micro switch consists of the following main components:

-

Actuator: The external part that receives mechanical force (plunger, lever, or roller)

-

Spring mechanism: Provides the snap-action movement

-

Movable and fixed contacts: Conduct or interrupt the electrical circuit

-

Housing (case): Protects internal components, often made of plastic or metal

-

Terminals: Electrical connection points (COM, NO, NC)

This compact and robust construction allows micro switches to perform reliably in limited spaces.

How To Maintain a Micro Switch

Proper maintenance can significantly extend a micro switch's service life:

-

Regular Cleaning: Use dry compressed air to remove dust and debris around the switch. Avoid chemical solvents that may corrode the housing or internal parts.

-

Inspect the Actuator: Ensure moving parts like levers or rollers operate smoothly without sticking or deformation.

-

Electrical Inspection: Periodically check contact continuity and condition using a multimeter to detect poor contact or welding.

-

Securing Mounting: Check that mounting screws are tight, ensuring the switch is firmly secured in place to prevent malfunction or damage from vibration.

-

Record & Replacement: For high-cycle applications, log operational counts or schedule periodic inspections. Perform preventive replacement before the expected end of its service life.

Summary

Micro switches are compact, fast-acting, and highly reliable components used for precise control and detection in many industries. Understanding what a micro switch is, how it works, how it is constructed, and how to use and maintain it correctly helps ensure long service life and stable performance. By following proper usage precautions and maintenance practices, micro switches can deliver accurate and dependable operation even in demanding environments.