1. What are Limit Switches?

A limit switch is an electromechanical device that is used to detect the presence, absence, or position of an object. It operates by converting mechanical motion into an electrical signal, which can then be used to control a variety of processes or devices. Limit switches are commonly used in industrial automation, robotics, and other applications where precise control of mechanical motion is required.

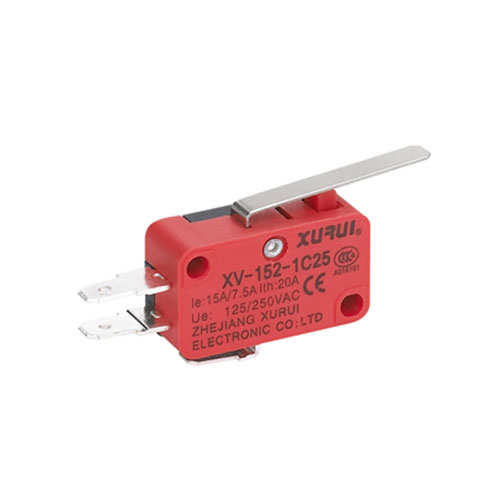

At its core, a limit switch consists of a set of electrical contacts that are opened or closed by a mechanical actuator. The actuator can be a lever, roller, plunger, or other type of mechanical device that is moved by the object being detected. When the object comes into contact with the actuator, it causes the contacts to change state, either opening or closing the electrical circuit.

2. Styles of Limit Switches

There are several different styles of limit switches, each designed for specific applications and environments. Some of the most common styles include:

Basic Limit Switches

These are the simplest form of limit switches and are typically used in applications where a simple on/off signal is required. They consist of a single set of contacts that are opened or closed by a mechanical actuator, such as a plunger or lever. Basic limit switches are often used in conveyor systems, machine tools, and other industrial applications.

Roller Limit Switches

Roller limit switches use a roller as the actuator, which is designed to make contact with the object being detected. The roller helps to reduce friction and wear, making these switches suitable for use in high-speed or high-impact applications. Roller limit switches are commonly used in packaging machines, material handling systems, and other applications where the object being detected is moving at a high speed.

Lever Limit Switches

Lever limit switches use a lever as the actuator, which can be positioned at different angles to detect the presence or position of an object. The lever can be designed to pivot, rotate, or swing, depending on the application. Lever limit switches are often used in applications where the object being detected is moving in a linear or rotational motion, such as in elevators, cranes, and other heavy machinery.

Proximity Limit Switches

Proximity limit switches are non-contact switches that use electromagnetic fields, capacitance, or other technologies to detect the presence of an object without physical contact. These switches are ideal for use in applications where physical contact with the object would cause damage or wear, such as in sensitive electronic equipment or food processing machinery. Proximity limit switches are available in a variety of styles, including inductive, capacitive, and magnetic types.

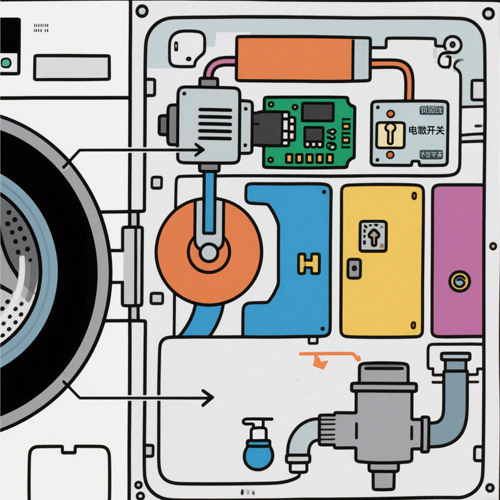

3. Real-World Application Scenarios

Industrial Automation

Workpiece Positioning: Electromechanical switches detect conveyor belt stops

Robot Safety: Proximity switches prevent collisions in robotic arms

Lifting Equipment: Limit switches stop cranes at safe height limits

Food & Beverage

Bottling Lines: Capacitive switches verify bottle presence without contact

Oven Monitoring: High-temperature rated switches check door closure

Automotive

Power Window Control: Sensitive limit switches detect window end positions

Brake Systems: Proximity sensors monitor brake pad wear

Limit Switch Working Principle

A limit switch operates through a mechanical trigger and electrical action:

Mechanical Trigger:

An object (e.g., a machine part) physically contacts the switch’s actuator (lever, roller, or plunger).

This force moves the actuator, compressing internal springs.

Electrical Action:

The actuator’s movement opens or closes electrical contacts inside the switch.

Normally Open (NO): Contacts close when triggered, completing the circuit.

Normally Closed (NC): Contacts open when triggered, breaking the circuit.

This signal is sent to a controller (e.g., PLC) to stop, reverse, or adjust machinery.

Symbols of Limit Switches

In electrical schematics, limit switches are represented by specific symbols that indicate their type and function. The most common symbols for limit switches include:

1. Normally Open (NO) Limit Switch Symbol

The normally open limit switch symbol is represented by a switch that is open when the actuator is not activated, and closed when the actuator is moved. The symbol typically consists of a rectangle with a diagonal line through it, indicating the open contacts, and an arrow indicating the direction of the actuator movement.

2. Normally Closed (NC) Limit Switch Symbol

The normally closed limit switch symbol is represented by a switch that is closed when the actuator is not activated, and open when the actuator is moved. The symbol typically consists of a rectangle with a diagonal line through it, indicating the closed contacts, and an arrow indicating the direction of the actuator movement.

3. Limit Switch with Both NO and NC Contacts Symbol

Some limit switches have both normally open and normally closed contacts, which can be used to provide multiple signals or to control different devices. The symbol for a limit switch with both NO and NC contacts typically consists of two rectangles, one for the NO contacts and one for the NC contacts, with an arrow indicating the direction of the actuator movement.

Proximity sensor vs. limit switch

| Dimensions | Proximity sensor | Limit switch |

| Working principle | Non-contact (electromagnetic, optical, magnetic, etc. induction) | Contact (physical touch triggers mechanical/electrical contacts) |

| Detection method | No contact is required, objects are sensed within the detection range | Must directly touch the switch mechanical parts |

| Response speed | Fast (nanoseconds to milliseconds) | Slower (mechanical action delay, milliseconds) |

| Lifespan | Long (no mechanical wear) | Short (contacts/mechanical parts are easy to wear) |

| Environmental adaptability | Some types are sensitive (such as photoelectric afraid of dust), some are durable (such as inductance) | Dust and impact resistant, but mechanical parts may rust/jam |

| Cost | High initial cost, low maintenance cost | Low initial cost, high maintenance cost (regular inspection required) |

|

Typical applications |

High-speed sorting, robot positioning, liquid level detection, precision equipment | Elevator limit, crane travel control, heavy machinery safety lock |

Can You Run a Furnace Without a Limit Switch?

No. A furnace’s high-limit switch is a critical safety component. It monitors temperature and shuts off the burner if overheating occurs (e.g., due to blocked airflow or fan failure). Operating a furnace without this switch risks:

Fire hazards from uncontrolled heat.

Equipment damage to heat exchangers or ducts.

Carbon monoxide leaks due to incomplete combustion.

Modern furnaces are designed to fail safely, meaning they will not operate if the limit switch is faulty or missing. Always replace a malfunctioning limit switch promptly.

Conclusion

Limit switches are indispensable for automation, safety, and precision. From simple mechanical designs to advanced proximity sensors, they ensure machinery operates within safe parameters while enabling complex processes. Understanding their working principles, styles, and applications helps engineers and technicians design safer, more efficient systems. Whether in a factory or a household furnace, these devices silently guard against malfunctions, proving that small components can have an outsized impact.