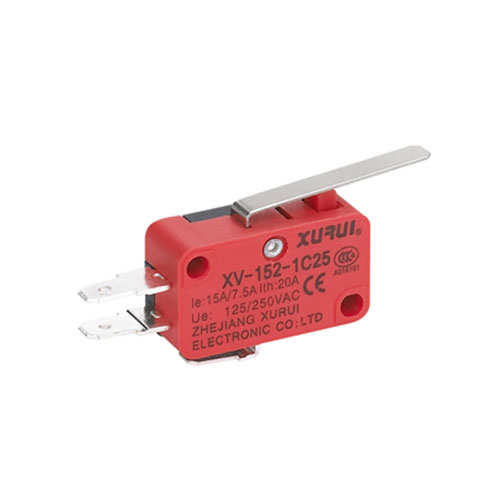

A micro switch, also known as a miniature snap-action switch, is an electromechanical component designed to control electrical circuits with precise, rapid on/off switching triggered by minimal mechanical force—such as pressure, displacement, or contact. Its defining feature is a snap-action mechanism, enabled by a spring-loaded structure that ensures instantaneous contact movement, minimizing arcing and delivering reliable performance over millions of operation cycles.

Micro Switch Working Principle and Core Applications

Inside a micro switch, a plunger, lever, or roller transfers external force to a spring-biased contact system. When the actuation force exceeds a threshold, the contacts "snap" between states, completing or interrupting the circuit in microseconds. This precision makes it ideal for:

- Consumer Electronics: Mouse clicks, smartphone buttons, and wearable device controls.

- Automotive Systems: Brake light activation, power window limits, and airbag deployment sensors.

- Industrial Machinery: Limit switches for robotic arms, conveyor belt safety controls, and equipment interlocks.

Micro switch type

|

Type |

Structural Design |

Trigger Mechanism |

Advantages |

Limitations |

Typical Applications |

|

Straight-Acting |

Compact design (5–10mm³), direct plunger contact |

Direct pressure on plunger compresses spring |

Ultra-miniaturized, fast response (<5ms) |

Narrow force range (0.1–0.5N), vibration-sensitive |

Earbud controls, smartwatch buttons |

|

Lever-Activated |

Adjustable lever arm for angled triggering |

Lever amplifies motion to reduce actuation force |

Flexible installation, customizable 行程 |

Slightly lower mechanical life (10⁶–5×10⁶ cycles) |

Printer paper sensors, appliance door switches |

|

Roller-Activated |

Roller-tipped plunger for rolling contact |

Roller converts sliding to rolling friction |

High wear resistance (70% less surface damage) |

Bulkier design, 20–30% higher cost |

Industrial limit switches, conveyor belts |

|

Solid-State (MEMS) |

No mechanical contacts; MEMS sensor-based |

Pressure changes capacitance/resistance in MEMS chip |

Unlimited lifespan (theoretical 10⁹ cycles), 50g vibration resistance |

Requires external power, complex circuitry |

Aerospace sensors, medical device controls |

Considerations for selecting a Micro Switch

When choosing a micro switch, prioritize these factors to balance performance and cost:

• Actuation Force:

Light-touch applications (e.g., wearables): Opt for straight-acting switches (0.1–0.5N).

Industrial use (e.g., machinery): Select roller/lever types (1–5N) for stable triggering.

• Electrical Load:

Low-load circuits (<1A): Single-pole single-throw (SPST) switches suffice.

High-load systems (10A+): Use double-pole double-throw (DPDT) switches for dual-circuit control.

• Environmental Resistance:

High-temperature environments (>125°C): Choose ceramic-encased solid-state switches (Temperature resistant up to 200°C).

Wet/humid conditions: Select IP67-sealed mechanical switches with gold-plated contacts to prevent corrosion.

• Space Constraints:

Miniature devices: Straight-acting or MEMS switches (≤3mm³).

Standard applications: Lever/roller types offer a balance of size and durability.

Why are micro switches so important?

Micro switches bridge the gap between mechanical input and electrical control, driving precision in everything from everyday gadgets to critical industrial systems. By understanding their types—from traditional mechanical designs to advanced solid-state MEMS technology—and matching them to specific needs, engineers and designers can optimize reliability, lifespan, and cost-effectiveness. As smart devices and automation continue to evolve, the humble micro switch remains a cornerstone of dependable, precise switching solutions.