A brief description of micro switches.

(1) General terms

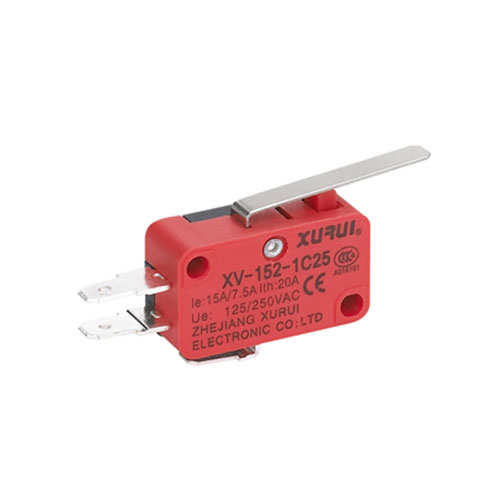

Micro switch: A switch with a contact structure that has a tiny contact interval and a snap-action mechanism to switch with a specified stroke and a specified force, covered with an enclosure, and with a drive lever outside. (Hereinafter referred to as a switch) with contacts: Among the switch types, the function of a switch is realized by mechanical switching of contacts compared to a semiconductor switch with switching characteristics. Contact form: An electrical input/output circuit that forms a contact according to various applications.

Rating: A value that is generally used as a guaranteed reference for switch characteristics and performance, such as rated current, rated voltage, etc., provided that specific conditions (type of load, current, voltage, frequency, etc.) are met.

Resin fixing (plastic sealing terminal): After the terminal part is wired with wires, the part is fixed by filling with resin, eliminating the exposed charged parts to improve the anti-drip method.

Insulation resistance: refers to the resistance value between the non-connected terminals, between the terminals and uncharged metal parts, between the terminals and ground.

Withstanding voltage: in the specified measurement parts after adding 1 minute of high voltage, will not cause insulation damage to the critical value.

Contact resistance: The resistance of the contact part of the contact, but generally indicates the resistance value of the conductor resistance including the spring and terminal parts.

Vibration resistance: The vibration range in which the closed contact does not separate due to vibration when the micro switch is in use for more than a specified period of time.

Shock resistance: Durable shock The shock that the microswitch will not be damaged by the mechanical shock to any part of the microswitch during transportation or installation and that satisfies the range of action characteristics.

False-action shock? The shock range in which the contact closed by the shock during the use of the micro switch is not separated for more than a specified period of time.

(2) Terms related to life

Mechanical life: The life of the switch when the contact is not energized and the over-travel (OT) is set to the specified value at the specified operating frequency to make it operate.

Electrical life: The switching life when the rated load is connected to the contact and the over-travel (OT) is set to the specified value at the specified operating frequency.

(3) Standard test condition

The test conditions of the switch are as follows.

Ambient temperature: 20±2℃, Relative humidity: 65±5%RH, Air pressure: 101.3kPa

(4) N level reference value

indicates the fault level at 60% reliability (λ60).

λ60=0.5×10-6/time means that the failure rate is less than time under the reliability of 60%.

(5) Shape and type of contact

(6) Contact interval

The contact interval is specified as 0.25mm, 0.5mm, 1.0mm, 1.8mm 4 kinds. Contact interval is the target of the design. If the minimum contact spacing is required for use, please check and select separately. For the same switching mechanism, the smaller the contact spacing, the smaller the MD, the higher the sensitivity, and the longer the mechanical life (life), but the DC breaking performance, vibration resistance, and shock resistance are not favorable. Microswitches will lose contacts due to current switching, the contact interval becomes larger, and the sensitivity decreases when the MD increases, so in order to achieve high sensitivity when using microswitches with a contact interval of 0.25mm, the switching current must be kept small to reduce the loss of contacts caused by current switching. Products with large contact interval, vibration resistance, shock resistance and breakage performance is good.

(7) Speed mechanism

The quick-action mechanism allows the movable contact to move quickly from a fixed contact to other fixed contacts, without being affected by the operating speed as much as possible. For example, even if the gate switch, if the handle is operated quickly, the action will become faster, but the speed of the operating handle and the speed of contact movement related to this mechanism is not called fast-acting type, but called slow-acting type. The faster the switching speed of the contact, the shorter the duration of the arc generated between the contacts.

This results in less consumption and damage to the contact and maintains stable characteristics. However, in the switching speed, in addition to effectively reduce the amount of arcing speed limit (economic speed), there are also mechanical problems of the limit, in particular, when the closed circuit if the switching speed is too fast, movable contacts and fixed contacts of the impact energy will become larger, the impact of the formation of jump phenomenon (vibration or friction closure) will generate arcing, this will be a serious loss of contacts, and sometimes fail to open the circuit, resulting in the melting of the contacts. The spring mechanism with a dead point (the critical point of action when jumping from one state to another) is generally used for such a fast-acting mechanism.